A molded case circuit breaker (MCCB) is a type of breaker used to protect electrical circuits from overcurrents arising from overload, short circuits, or faulty wiring.

It is like a miniature circuit breaker (MCB), however, MCCB has higher features.

Molded case circuit breakers have a higher current rating of up to 2500 amp and an adjustable trip settings, making them useable on both low voltage, medium, and high voltage substations for circuit protection.

Where and what is a molded case circuit breakers (MCCB) used for?

Molded case circuit breakers can be used in any environment, be it residential applications, industrial, or commercial systems.

It helps to protect against overload, short circuits, and ground faults using their thermomagnetic and electromagnetic trip mechanisms.

Parts of MCCB.

- Molded case or frame: This provides insulated housing to the breakers’ components.

- Operating mechanism: It controls the opening and closing of the contact.

- Arc extinguishers: This closes and opens the arc.

- Trip units: It trips the operating mechanism.

- Contact: Metallic conductors that carry currents.

How a molded case circuit breaker works

Like miniature circuit breakers, the molded case switch also uses a temperature sensitive device (thermal element) and a current sensitive electromagnetic device (the magnetic element) to detect and interrupt faulty currents. This enables them to provide:

- Overload protection,

- Short circuit protection,

- Electrical switch for disconnection.

Overload protection

MCCB provides overload protection with its thermal element (the bimetallic contact).

This contact comprises two metals that expand at different rates when exposed to high temperature.

Under working conditions, the contact closes and allows current flows through it.

When the current exceeds the adjusted trip value, the contact heats up and eventually bends away. This leads to circuit interruptions.

Short circuit protection

Besides overload protection, this switchgear also protects against faulty currents using electromagnetic induction.

The MCCB produces a small electromagnetic force as the current flows through the solenoid coil.

When a short circuit occurs, higher currents flow through the breaker. This makes the solenoid coil produce a strong electromagnetic field that forces the trip bar to open the circuit.

Electrical switch for disconnection

Besides the tripping mechanism of the breaker, it also has a manual switch ON and OFF the circuit during emergencies or maintenance.

Note: MCCB doesn’t protect against electric shock, GFCI does that.

Types of molded case circuit breaker.

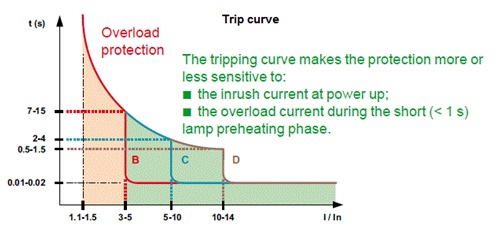

There are five types of MCCBs according to their trip curve. They include:

Type B

This breaker trips when the current rate is 3 to 5 times higher than the current rating. They are used in domestic appliances and in light commercial applications with low surge current.

Type C

This circuit breaker trips when the current is 5 to 10 times above their trip curve.

They are used in commercial or industrial applications with moderate surge currents.

Examples include transformers, printers, fluorescent servers, and pcs.

Type D

These MCCBs trip when the current is 10 to 20 times above the trip curve.

They are used in big industrial and commercial applications with high inrush current. For example; X-ray machines, pumps, large winding motors, big transformers, etc.

Type K

This MCCB trip when the current rate is 10 to 12 times higher than the current rating. They are suitable for inductive and motor loads with high inrush currents.

Type Z

These MCCB trips when the current is 2 to 3 times higher than the trip curve. They are sensitive to short circuits and are suitable for protecting highly sensitive devices such as semiconductor devices.

Difference between MCCB and MCB

MCBs and MCCBs are the same. Their differences lie only in their trip curve. The trip curve of MCBs is not adjustable and is all sub-100 amp devices designed for low-voltage circuits.

Meanwhile, MCCBs have an adjustable trip curve and can be used on high-voltage circuits.

MCCB Rating.

Before making your choice of a circuit breaker, be it MCB or MCCB, make sure you understand the rating or specification. They come in different sizes for different purposes, so be sure your selection tallies with your intention.

Here are the things to watch out for:

- Rated frame current (Inm): This shows the maximum current the breaker can withstand. It defines the upper limit of the adjustable trip, current range, and the frame size of the breaker.

- Rated current (In): This determines when the breaker trips because of overload. And unlike the MCB that has fixed rated current, MCCB is adjustable.

- Rated insulation voltage (UI): This shows the maximum voltage the breaker can withstand in a lab test. It is usually higher than the rated working voltage, to provide a safety margin during field operation.

- Rated working voltage (UE): This defines the rated voltage for the continuous operation of the breaker. It is usually the same or very close to the system voltage.

- Rated impulse withstanding voltage (UIMP): This shows the value of transient peak voltage the breaker can withstand from switching surges or lighting strikes. This value shows the ability of the breaker to withstand transient overvoltages from lightning strikes. The standard size for impulse testing is 1.2/50 μs.

- Operating short-circuit breaking capacity (LCS): This is the highest fault current the breaker can trip without damaging permanently. MCCBs are reusable after interrupting a faulty current, provided they do not exceed that value. The higher the LCS, the more reliable the MCCB.

- Ultimate short-circuit breaking capacity (ICU): This is the highest fault current the electrical breaker can withstand. If the faulty current exceeds the value, the breaker will not trip again and will take another protection mechanism with a higher breaking capacity.

- Mechanical life: It shows the number of times we can manually operate the breaker before failure.

- Electrical life: Shows the number of times the breaker can trip before failure.

MCCB testing

According to ANSI/NEMA AB 4, guidelines for inspection and preventive maintenance of MCCBs, the following test can be useful in verifying the operational level of an MCCB.

Insulation resistance test

To determine the level of insulation between the phases and across the supply and load terminals.

Inverse time overcurrent trip test

This checks the inverse time overcurrent tripping function of the breaker.

Individual pole resistance test (millivolt drop test)

To evaluate the electrical integrity of the internal connections and contacts of the breaker.

Instantaneous overcurrent trip test

To check the operation of the instantaneous trip functions under field test conditions.

Mechanical operation test

To check if the operating mechanism is working fine.

Rated hold-in test

Check the capability of the breaker in carrying the rated current.

Mccb maintenance

Since the breakers come in an enclosed form, they rarely require maintenance.

The preventive maintenance you may give them depends on the operating conditions and includes:

- Cleaning of the breakers component to remove dirt.

- Manual inspection to check for damaged or burnt parts and others.

- Occasional lubrication of the body parts.

Conclusion

Though MCCBs offer protection against overload and power surges, it is important you consider the power rating before buying one.

Always go for the one that is compatible with your appliances, since compatibility and maintenance result in maximum performance.

Related articles